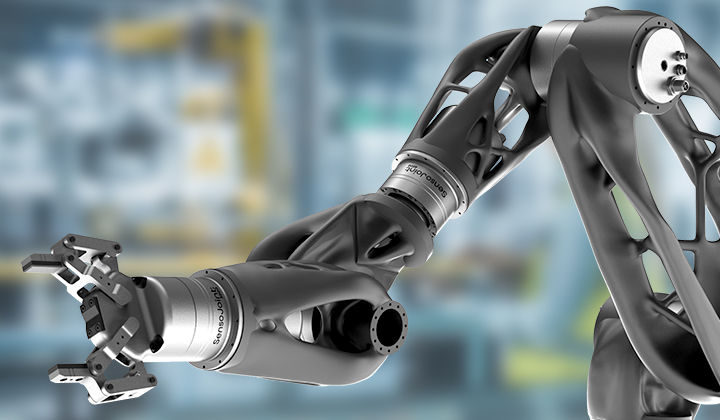

From industrial robots for human-robot collaboration (HRC) to medical robots to force feedback solutions – with its patented torque sensors, and unique integration and control know-how, Sensodrive has created a new era in robotics. This market-leading sensor technology is also at the heart of the SensoJoint – a ready-to-install complete drive that makes the development of sensitive robotics solutions faster and more efficient than ever before.

This unique Plug & Play actuator made in Germany not only sets new standards in terms of performance, precision and quality – thanks to its perfectly compatible individual components, SensoJoints are as compact as they are light and can be integrated optimally into any robotics concept.

Developing your own robotics solutions costs time and money. SensoJoints are ready to install and easy to integrate thanks to their standard hardware and software interfaces. In addition, they are already fully safety-certified1 and fulfil all key safety requirements for HRC robotics.

SensoJoints are available in five sizes and can also be supplied in individual designs and performance levels if required. So you receive a customised actuator for each application that can be integrated into your products right away – without long development times.

From the innovative Sensodrive torque sensor to the market-leading HarmonicDrive® gear to the powerful motors – only high-quality components that are perfectly compatible with each other are installed in the SensoJoints drive modules.

Sensodrive torque technology is used in the cobots of many renowned industrial and medical robot manufacturers. We are making this innovative technology available in a complete drive for the first time with SensoJoints, offering you the highest level of safety for your robotics solutions.

SensoJoints are already certified in accordance with all key international safety standards - such as e. g: ISO 13849, IEC 62061, IEC 61508 and DIN ISO/TS 15066 (from 2024). So there's no need to go through any more lengthy certification processes.

Thanks to market-leading sensor technology and precise, highly safe control technology, SensoJoints offer maximum reliability in every respect so that robots and humans can work together safely without protective fences.

Sensodrive only uses high-quality components that are perfectly compatible with each other. SensoJoints are therefore completely maintenance-free and set new standards in terms of their durability.

STO - Safe Torque Off

|

Safe Torque Off interrupts the power supply to the drive while the brake is applied. The joint controller is deactivated and the joint is mechanically stopped.The STO function ensures that no torque can act on the motor and is therefore used in industrial machines, robots and force feedback solutions for emergency stop and safety stop functions. |

SBC – Safe Brake Control

|

Safe Brake Control (SBC) ensures that the brakes are locked when Safe Torque Off (STO) is activated. This ensures that lifted loads are braked in good time and do not drop. This is how SBC ensures the reliable implementation of emergency and safety stops in industrial machines, robots and force feedback solutions. |

SBT – Safe Brake Test

|

After appropriate implementation in the safety control system, the Safe Brake Test (SBT) safety function ensures that the brakes can apply the required holding torque at all times by cyclically checking them. In combination with Safe Torque Off (STO) and Safe Brake Control (SBC), it guarantees an absolutely safe braking and stopping system. |

SS1 – Safe Stop 1

|

If the drives were simply switched off, they would run down, which could lead to hazards. With the help of the Safe Stop 1 (SS1) safety function, the SensoJoint drive is therefore brought to a controlled standstill. As soon as the motor movement stops, the STO function is automatically triggered. This allows the drive to be fast and safely stopped and the brake is noticeably protected. |

SS2 – Safe Stop 2

|

The SensoJoint drive is brought to a standstill in a controlled manner and remains in control even when at a standstill. By keeping the drive powered, the position can be held precisely, and it is quicker to move on after the safety stop than with other stop functions. |

SOS – Safe Operating Stop

|

With the Safe Operating Stop (SOS) safety function, the SensoJoint reliably monitors the holding of a position (for example after activation of the SS2 function). The drive may only move within a precisely defined position window. If the permissible position tolerance is exceeded, a suitable error reaction takes place, e.g. activation of the STO function. |

High-quality lightweight materials, market-leading torque sensors and precise finishing ensure reliable product quality that is worth the investment. SensoJoints are extremely robust and completely maintenance-free.

Size and weight are reduced to an absolute minimum thanks to the perfect compatibility of all components and the use of sturdy, lightweight materials.

The innovative Sensodrive torque control ensures that motions are executed with maximum precision – without any oscillation.

Particularly powerful motors and market-leading gears with output bearing enable safe and reliable power transmission.

Advanced Position Control

|

The active vibration damping reliably prevents unwanted oscillations and, with precise friction compensation, enables fine adjustment of the smallest vibrations – even with higher inertias and loads. SensoJoints are thus guaranteed to securely hold a defined position, even when affected by disturbing forces, e.g. for the vibration-free positioning of surgical microscopes. |

Advanced Velocity Control

|

The precise speed control ensures smooth, steady control even at low speeds of less than 1°/s. Its active friction compensation reliably prevents the occurrence of stick-slip effects as well. |

Advanced Torque Control

|

SensoJoints impress with their highly precise and dynamic torque control at the output:

|

Thanks to their comprehensive safety functions, SensoJoint complete drives meet all the requirements of safety integrity level SIL3/PLe. They are already fully safety-certified* in accordance with IEC 61508, IEC 62061 as well as ISO 13849, thus saving you significant time and costs when meeting the requirements of ISO 10218 and ISO/TS 15066 compared to developing your own solutions.

For use in less safety-critical areas, our SensoJoint complete drives are also available in a

basic version with only two safety functions – the efficient solution for all applications that

do not require extended safety certification to SIL3/PLe level.

SensoJoints also set new standards in the medical sector. Their torque sensors and state-of-the-art control technology can prevent e.g. disruptive and sometimes even dangerous vibrations of surgical microscopes, thanks to groundbreaking technology.

SensoJoints are the perfect sensitive drive solution for robot joints. They are used in lightweight robots by renowned manufacturers around the world to enable successful human-robot collaboration (HRC) and delicate assembly work.

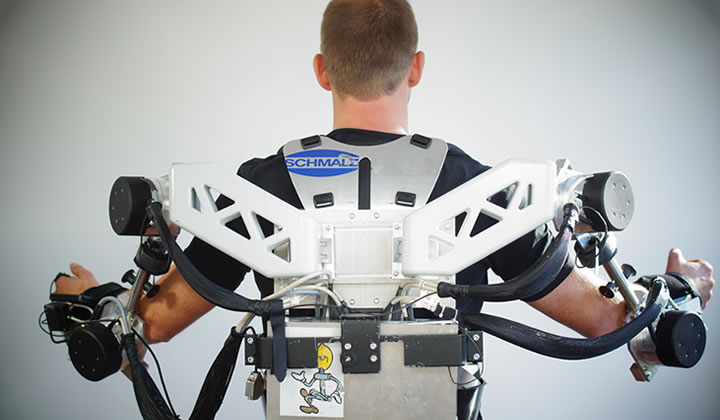

Due to their sensitivity and extremely compact design, SensoJoints are also perfect for force feedback applications. They guarantee the safe interaction of people and machines without protective devices and enable realistic simulations even on a large scale.

In the factory of the future, SensoJoints will improve efficiency in a wide variety of areas. For example, as part of a modern exoskeleton to support lifting heavy loads. Or for maintaining perfectly steady tension in winding machines.

Let our experts demonstrate the advantages that SensoJoints can offer your industry and your company. We will be happy to advise you on an individual basis.

* Certification process completion expected in Q1 2024.

from left to right:

From the particularly small SensoJoint 3000 for use in hand axes to the powerful SensoJoint 7000 for large main axes – the innovative complete drives are available in 5 standard sizes and can also be individually customised to your requirements if necessary.

Technical data SensoJoint 3000

| SensoJoint Serie |

3000 | ||

| Gearbox type | Harmonic Drive® | ||

| Torque sensor | fully integrated | ||

| Motor | BLDC motor | ||

| Motor controller | fully integrated | ||

| Brake | fully integrated | ||

| Supply voltage [VDC] | 24 - 48 | ||

| Communikation interface | EtherCAT® | ||

| Safety functions | see table | ||

| Main bearing | Cross roller bearing | ||

| Position sensor on the output side | 19bit absolut 18bit multiturn |

||

| Model | 3005 | 3008 | 3010 |

| Gear ratio | 1:51 | 1:81 | 1:101 |

| Maximum input current [A]* | 4 | 3 | 3 |

| Rated torque [Nm]* | 5,4 | 7,8 | 7,8 |

| Maximum torque [Nm]* | 18 | 23 | 28 |

| Rated speed [min-1]* | 39 | 24 | 19 |

| Maximum speed [min-1]* | 115 | 70 | 55 |

| Length [mm] | 150.5 | ||

| Diameter [mm] | 90.0 | ||

| Hollow shaft diameter [mm] | 9.0 | ||

| Weight [kg] | approx. 1.3 | ||

| 3D-Model (STEP) | SensoJoint 3000 | ||

| Further technical information | We would be pleased to answer any questions you may have and send you the CAD data of our SensoJoints | ||

*At 48 DC. SensoJoint Version A.3/B.0.

Technical data SensoJoint 4000

| SensoJoint Serie |

4000 | ||

| Gearbox type | Harmonic Drive® | ||

| Torque sensor | fully integrated | ||

| Motor | BLDC motor | ||

| Motor controller | fully integrated | ||

| Brake | fully integrated | ||

| Supply voltage [VDC] | 24-48 | ||

| Communikation interface | EtherCAT® | ||

| Safety functions | see table | ||

| Main bearing | Cross roller bearing | ||

| Position sensor on the output side | 19bit absolut 18bit multiturn |

||

| Model | 4005 | 4008 | 4010 |

| Gear ratio | 1:51 | 1:81 | 1:101 |

| Maximum input current [A]* | 6 | 6 | 6 |

| Rated torque [Nm]* | 16 | 22 | 24 |

| Maximum torque [Nm]* | 34 | 43 | 54 |

| Rated speed [min-1]* | 39 | 24 | 19 |

| Maimum. speed [min-1]* | 115 | 70 | 55 |

| Length [mm] | 164.1 | ||

| Diameter [mm] | 90.0 | ||

| Hollow shaft diameter [mm] | 9.0 | ||

| Weight [kg] | approx. 1.7 | ||

| 3D-Model (STEP) | SensoJoint 4000 | ||

| Further technical information | We would be pleased to answer any questions you may have and send you the CAD data of our SensoJoints | ||

*At 48 VDC. SensoJoint Version A.3/B.0.

Technical Data SensoJoint 5000

| SensoJoint Serie |

5000 | ||||

| Gearbox type | Harmonic Drive® | ||||

| Torque sensor | fully integrated | ||||

| Motor | BLDC motor | ||||

| Motor controller | fully integrated | ||||

| Brake | fully integrated | ||||

| Supply voltage [VDC] | 24-48 | ||||

| Communikation interface | EtherCAT® | ||||

| Safety functions | see table | ||||

| Main bearing | Cross roller bearing | ||||

| Position sensor on the output side | 19bit absolut 18bit multiturn |

||||

| Model | 5005 | 5008 | 5010 |

5012 | 5016 |

| Gear ratio | 1:51 | 1:81 | 1:101 | 1:121 | 1:161 |

| Maximum intput curent [A]* | 6 | 6 | 6 | 6 | 6 |

| Rated torque [Nm]* | 33 | 44 | 52 | 52 | 52 |

| Maximum torque [Nm]* | 62 | 96 | 107 | 113 | 120 |

| Rated speed [min-1]* | 39 | 24 | 19 | 16 | 12 |

| Maximum speed [min-1]* | 115 | 70 | 55 | 45 | 37 |

| Length [mm] | 172.5 | ||||

| Diameter [mm] | 100.0 | ||||

| Hollow Shaft diameter [mm] | 9.0 | ||||

| Weight [kg] | approx. 2.0 | ||||

| 3D-Model (STEP) | SensoJoint 5000 | ||||

| Further technical information | We would be pleased to answer any questions you may have and send you the CAD data of our SensoJoints | ||||

*At 48 VDC. SensoJoint Version A.3/B.0.

Technical Data SensoJoint 6000

| SensoJoint Serie |

6000 | |||

| Gearbox type | Harmonic Drive® | |||

| Torque sensor | fully integrated | |||

| Motor | BLDC motor | |||

| Motor controller | fully integrated | |||

| Brake | fully integrated | |||

| Supply voltage [VDC] | 24-48 | |||

| Communikation interface | EtherCAT® | |||

| Safety functions | see table | |||

| Main bearing | Cross roller bearing | |||

| Position sensor on the output side | 20bit absolut 18bit multiturn |

|||

| Model | 6005 | 6008 | 6010 | 6012 |

| Gear ratio | 1:51 | 1:81 | 1:101 | 1:121 |

| Maximum input current [A]* | 10 | 10 | 10 | 10 |

| Rated torque [Nm]* | 39 | 63 | 67 | 67 |

| Maximum torque [Nm]* | 98 | 137 | 157 | 167 |

| Rated speed [min-1]* | 39 | 24 | 19 | 16 |

| Maximum speed [min-1]* | 70 | 45 | 35 | 30 |

| Length [mm] | 192.4 | |||

| Diameter [mm] | 117.0 | |||

| Hollow shaft diameter [mm] | 13.0 | |||

| Weight [kg] | approx. 3.4 | |||

| 3D-Model (STEP) | SensoJoint 6000 | |||

| Further technical information | We would be pleased to answer any questions you may have and send you the CAD data of our SensoJoints | |||

*At 48 VDC. SensoJoint Version A.3/B.0.

Technical Data SensoJoint 7000

| SensoJoint Serie |

7000 | ||||

| Gearbox type | Harmonic Drive® | ||||

| Torque sensor | fully integrated | ||||

| Motor | BLDC motor | ||||

| Motor controller | fully integrated | ||||

| Brake | fully integrated | ||||

| Supply voltage [VDC] | 24-48 | ||||

| Communikation interface | EtherCAT® | ||||

| Safety functions | see table | ||||

| Main bearing | Cross roller bearing | ||||

| Position sensor on the output side | 20bit absolut 18bit multiturn |

||||

| Model | 7005 | 7008 | 7010 | 7012 | 7016 |

| Gear ratio | 1:51 | 1:81 | 1:101 | 1:121 | 1:161 |

| Maximum input current* | 10 | 12 | 12 | 12 | 12 |

| Rated torque [Nm]* | 76 | 118 | 137 | 137 | 137 |

| Maximum torque [Nm]* | 166 | 264 | 329 | 353 | 372 |

| Rated speed [min-1]* | 39 | 24 | 19 | 16 | 12 |

| Maimum. speed [min-1]* | 90 | 55 | 45 | 35 | 25 |

| Length [mm] | 204.0 | ||||

| Diameter [mm] | 145.0 | ||||

| Hollow shaft Diameter [mm] | 19.0 | ||||

| Weight [kg] | approx. 5.5 | ||||

| 3D-Model (STEP) | SensoJoint 7000 | ||||

| Further technical information | We would be pleased to answer any questions you may have and send you the CAD data of our SensoJoints | ||||

*At 48 VDC. SensoJoint Versiion A.3/B.0.

SensoJoint customized

We can develop the perfect solution for you – especially according to your requirements.

Please inquire!

Technical Data of all SensoJoints in comparison

| SensoJoint series |

3000 | 4000 | 5000 | 6000 | 7000 | |||||||||||||||

| Gearbox type | Harmonic Drive® | |||||||||||||||||||

| Torque sensor | fully integrated | |||||||||||||||||||

| Motor | BLDC motor | |||||||||||||||||||

| Motor controller | fully integrated | |||||||||||||||||||

| Brake | fully integrated | |||||||||||||||||||

| Supply voltage [VDC] | 24-48 | |||||||||||||||||||

| Communikation interface | EtherCAT® | |||||||||||||||||||

| Safety functions | see table | |||||||||||||||||||

| Main bearing | Cross roller bearing | |||||||||||||||||||

| Position sensor on the output side | 19bit absolut 18bit multiturn |

20bit absolut 18bit multiturn |

||||||||||||||||||

| SensoJoint Models | 3005 | 3008 | 3010 | 4005 | 4008 | 4010 | 5005 | 5008 | 5010 | 5012 | 5016 | 6005 | 6008 | 6010 | 6012 | 7005 | 7008 | 7010 | 7012 | 7016 |

| Gear ratio | 1:51 | 1:81 | 1:101 | 1:51 | 1:81 | 1:101 | 1:51 | 1:81 | 1:101 | 1:121 | 1:161 | 1:51 | 1:81 | 1:101 | 1:121 | 1:51 | 1:81 | 1:101 | 1:121 | 1:161 |

| Maximum input current [A]* | 4 | 3 | 3 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 10 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 |

| Rated torque [Nm]* | 5,4 | 7,8 | 7,8 | 16 | 22 | 24 | 33 | 44 | 52 | 52 | 52 | 39 | 63 | 67 | 67 | 76 | 118 | 137 | 137 | 137 |

| Maximum torque [Nm]* | 18 | 23 | 28 | 34 | 43 | 54 | 62 | 96 | 107 | 113 | 120 | 98 | 137 | 157 | 167 | 166 | 264 | 329 | 353 | 372 |

| Rated speed [min-1]* | 39 | 24 | 19 | 39 | 24 | 19 | 39 | 24 | 19 | 16 | 12 | 39 | 24 | 19 | 16 | 39 | 24 | 19 | 16 | 12 |

| Maximum speed (no load) [min-1]* | 115 | 70 | 55 | 115 | 70 | 55 | 115 | 70 | 55 | 45 | 35 | 70 | 45 | 35 | 30 | 90 | 55 | 45 | 35 | 25 |

| Length [mm] | 150.5 | 164.1 | 172.5 | 192.4 | 204.0 | |||||||||||||||

| Diameter [mm] | 90.0 | 90.0 | 100.0 | 117.0 | 145.0 | |||||||||||||||

| Hollow shaft diameter [mm] | 9.0 | 9.0 | 9.0 | 13.0 | 19.0 | |||||||||||||||

| Weight [kg] | approx. 1.3 | approx. 1.7 | approx. 2.0 | approx. 3.4 | approx. 5.5 | |||||||||||||||

| 3D-Model(STEP) | SensoJoint 3000 | SensoJoint 4000 | SensoJoint 5000 | SensoJoint 6000 | SensoJoint 7000 | |||||||||||||||

| Further technical information | We would be pleased to answer any questions you may have and send you the CAD data of our SensoJoints | |||||||||||||||||||

EtherCAT® and Safety over EtherCAT® are registered trademarks and patented technologies licensed by Beckhoff Automation GmbH, Germany.

*At 48 VDC. SensoJoint Versiion A.3/B.0.

SensoJoints not only accelerate the planning and development of new cobot solutions. Their compact design and standard interfaces also enable even faster prototype assembly.

Space, Industry 4.0, medical technology, the automotive industry ... the potential applications for the sensitive SensoJoint complete drives are almost unlimited. See for yourself.